Sand casting is the most traditional casting method, which is a casting method in which sand is used as the main molding material to prepare molds. Steel, iron and most non-ferrous alloy castings can be obtained by sand casting. Because the molding materials used in sand casting are cheap and easy to obtain, and the casting mold is easy to manufacture, it can be adapted to single-piece production, batch production and mass production of castings. It has been the basic process in casting production for a long time.

The basic process of the sand casting process mainly includes the following stages: mold making, sand mixing, molding, melting, pouring, and cleaning.

1. Mold manufacturing stage: Make molds according to the requirements of the drawings. Generally, wooden molds can be used for single-piece production, plastic molds and metal molds can be made for mass production, and templates can be made for large-scale castings.

2. Sand mixing stage: According to the requirements of sand mold manufacturing and the types of castings, qualified molding sand is prepared for molding/core making.

3. Modeling/core-making stage: including modeling (forming the cavity of the casting with molding sand), core making (forming the internal shape of the casting), and mold matching (putting the sand core into the cavity and closing the upper and lower sand boxes) . Molding is a key link in casting.

4. Smelting stage: Prepare the chemical composition according to the required metal composition, select a suitable melting furnace to melt the alloy material, and form a qualified liquid metal liquid (including qualified composition and qualified temperature).

5. Pouring stage: inject the qualified molten metal into the sand box equipped with the mold. Pay attention to the speed of pouring when pouring, so that the molten metal can fill the entire cavity. The pouring stage is relatively dangerous, so special attention should be paid to safety.

6. Cleaning stage: The purpose of cleaning is to remove sand, grinding and excess metal in the casting, and improve the surface appearance of the casting. After the molten metal is solidified after pouring, the molding sand is removed, the sprue and other accessories are removed, and the required casting is formed, and finally its defects and overall quality are inspected.

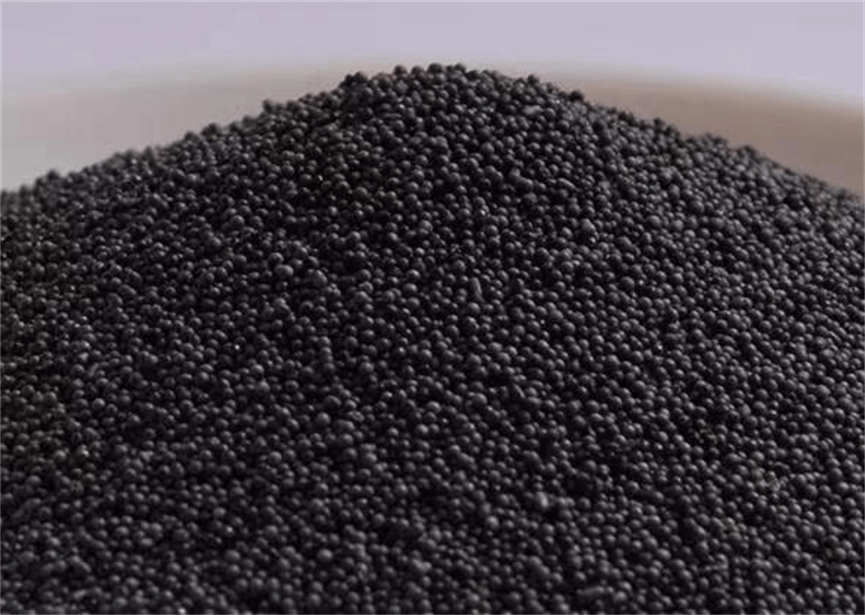

Ceramic sand has the advantages of high temperature resistance, no breakage, no dust, spherical shape, high air permeability, good filling performance, no silica dust hazard, etc. It is a green and environmentally friendly casting sand. It is suitable for sand casting (mold sand, core sand), V method casting, lost foam casting (filling sand), coating (ceramic sand powder) and other casting processes. It is used in automobile engines and auto parts, large cast steel, stainless steel, and iron castings, Non-ferrous alloy castings and other fields are widely used, known as green and environmentally friendly casting sand.

Post time: Jun-14-2023